Understand the Basics of Material Quality

When looking for a high-quality rubber shower door seal strip, the material is the first thing you need to focus on. Good seal strips are usually made of high-grade rubber or PVC materials that feel soft and flexible when touched. They shouldn’t be too hard or brittle, because hard materials are easy to crack after being used for a while, which will affect the waterproof effect. You can gently pull the seal strip to test its elasticity—high-quality ones can recover quickly without deformation. Also, pay attention to whether the material has a pungent odor. Inferior rubber products often emit strong chemical smells, which are not only harmful to health but also indicate poor material quality. High-quality shower door seal strips are non-toxic and odorless, meeting environmental protection standards that are safe for use in bathrooms.

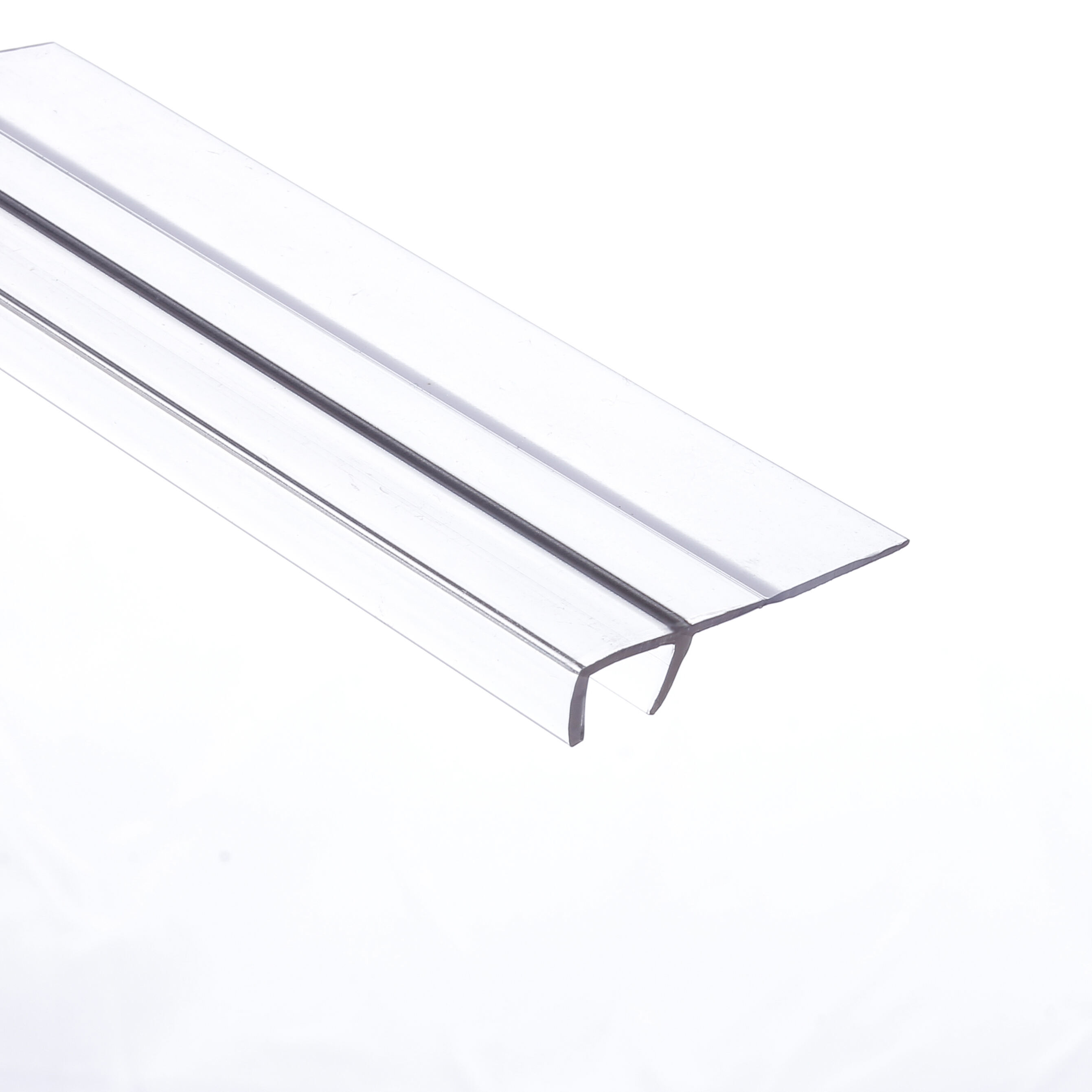

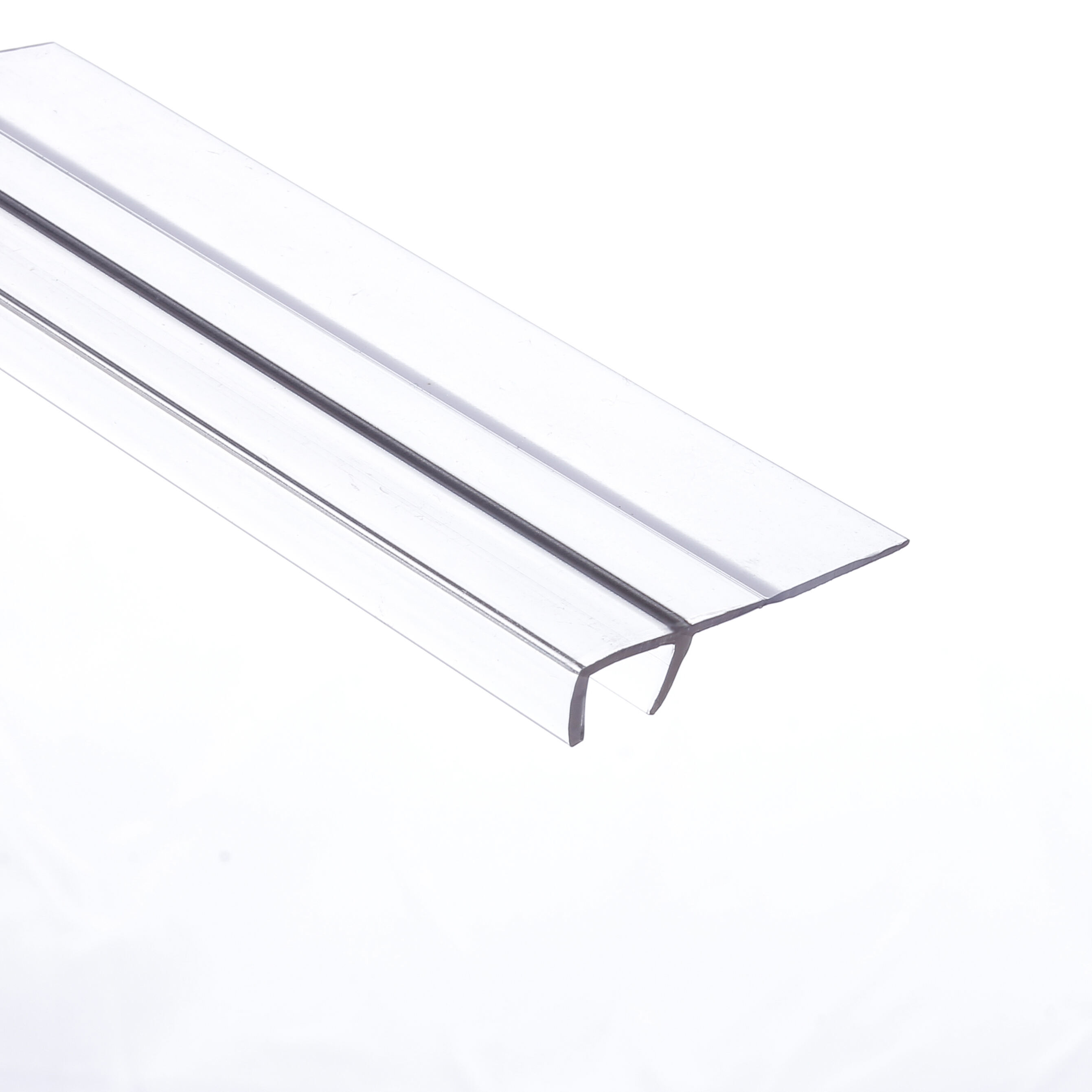

Check the Structural Design and Fit

The structural design of a shower door seal strip directly affects its sealing performance. A good seal strip should have a reasonable structure that fits closely with the shower door and the door frame. When checking, you can observe whether the edges are smooth and free of burrs, as uneven edges will lead to gaps and water leakage. For magnetic seal strips, the magnetic force is crucial. High-quality magnetic shower door seal strips can attract the door tightly, ensuring no water seeps through the gaps. You can test this by attaching the strip to the glass door—if it adheres firmly and doesn’t fall off easily, it’s a sign of good quality. Additionally, the size of the seal strip should match your shower door perfectly. Measure the thickness and length of your door before purchasing to ensure the strip fits snugly without being too loose or too tight. A well-fitted shower door seal strip will effectively block water from splashing out of the shower area.

Evaluate Durability and Resistance

Durability is another key factor in identifying a high-quality rubber shower door seal strip. Bathrooms are humid environments, so the seal strip must be resistant to water, corrosion, and mold. High-quality products are treated with special processes to prevent mold growth, which not only maintains hygiene but also extends the service life. You can check the product’s specifications or ask the manufacturer about its mold resistance. Also, consider the wear resistance of the seal strip. It should be able to withstand frequent opening and closing of the shower door without wearing out or breaking easily. Look for seal strips with thickened edges or reinforced structures, as these are more durable. Moreover, good seal strips should be able to withstand changes in temperature, not becoming stiff in cold weather or soft and deformed in hot conditions. This ensures consistent performance over a long period of time.

Verify Manufacturer Credentials and Quality Control

The reputation and strength of the manufacturer play an important role in the quality of the shower door seal strip. Choose manufacturers with rich production experience and good market reputation. For example, manufacturers with over 20 years of experience in producing seal strips usually have mature production technology and strict quality control systems. You can check if the manufacturer has relevant certifications, such as SGS certification, which indicates that the products meet international quality standards. Additionally, understand the manufacturer’s quality control process. A reliable manufacturer will conduct strict inspections on raw materials, production processes, and finished products to ensure that each shower door seal strip meets the required quality. You can also refer to customer reviews and feedback to learn about the actual use effect of the product.

Pay Attention to Installation and After-Sales Service

Although installation may seem simple, a high-quality shower door seal strip should be easy to install and come with clear installation instructions. Inferior products may have unreasonable designs that make installation difficult or require additional tools. Additionally, good after-sales service is an important guarantee of product quality. If you encounter problems during installation or use, the manufacturer should provide timely solutions. You can check if the manufacturer offers after-sales support, such as product replacement or repair services. A manufacturer that values customers will respond to inquiries patiently and solve problems efficiently. Choosing a product with good after-sales service not only ensures the use effect but also saves you trouble in the future.

Hot News

Hot News